Sourcing, Procurement & Purchasing opens the door to operational performance

Sourcing, procurement and purchasing are key departments of any organisation. Billions are spent every year in research of how to optimise this departments in order to save money, however, there is a common thread running through all of these methods that isn’t necessarily obvious at first: resource optimisation is the key to increasing operational performance, helping to improve the bottom line, and improving the customer experience.

Procurement & Purchasing, and the differences between them

The first point that should defined is procurement. Procurement is the process of discovering and agreeing on terms and purchasing goods, services, or other works from an outside source, typically through a tendering or competitive bidding procedure. Public procurement occurs when a government agency purchases products or services using this method.

When quality, quantity, time, and location are compared, procurement as an organizational process is meant to ensure that the buyer receives goods, services, or tasks at the best possible price. Corporations and government agencies frequently create methods to encourage fair and open competition for their businesses while limiting dangers such as fraud and collusion.

What exactly is procurement?

Procurement is the process of identifying, shortlisting, selecting, and acquiring suitable goods or services or works from a third-party vendor through a direct purchase, competitive bidding, or tendering process while ensuring timely delivery of the right quality and quantity.

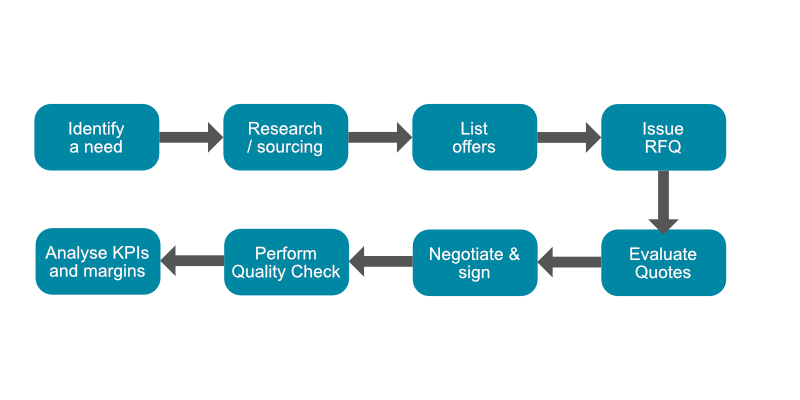

An end-to-end procurement process consists of the steps listed below:

Surveying the market.

Spotting potential suppliers.

Creating an approved list of vendors.

Spotting internal needs.

Creating a purchase order online.

Requesting proposals and evaluating quotations.

Selecting the right supplier and negotiating effectivelv.

Receiving goods and performing quality checks.

Developing and managing contracts.

Obtaining invoice approvals and fulfilling pavment terms.

Establishing a good supplier relationship.

What about Purchasing?

Purchasing is the process by which a company or organization acquires goods or services in order to achieve its objectives. Although numerous organizations seek to establish standards in the purchasing process, practices can vary widely amongst firms. Purchasing is a component of the larger procurement process, which encompasses expediting, supplier quality, transportation, and logistics.

more concretely…

Purchasing is the set of functions associated with acquiring the goods and services that an organization requires. Purchasing is a small subset of the broader procurement function. This process includes activities like ordering, expediting, receiving, and fulfilling payment.

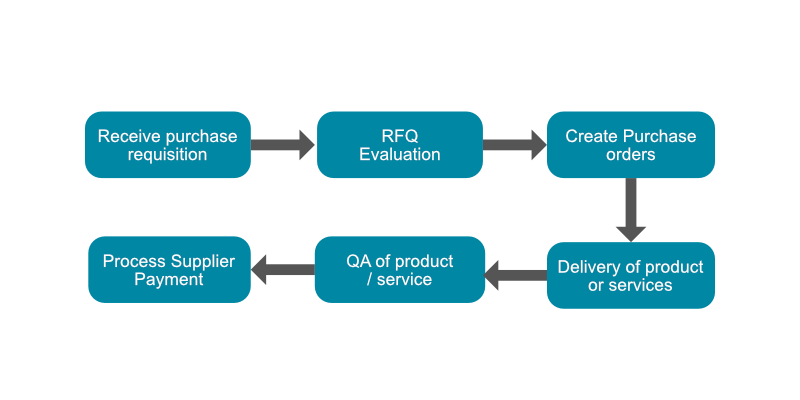

Listed below are the steps in the purchasing process:

Obtaining a purchase requisition.

Requesting proposals and evaluating quotations.

Dispatching official purchase orders.

Receiving products and services.

Checking the quality of delivered items.

Effecting payment to vendors.

Optimisation & liability reduction

The sourcing, procurement and purchasing processes are often optimised to reduce costs, increase efficiency and improve customer service. The three processes are often used together to get the best value for money and to ensure that a company has all the resources it needs to operate effectively. This can be done by using a variety of methodologies such as lean manufacturing, just-in-time production, total quality management (TQM) and six sigma.But there is a common thread running through all of these methods that isn’t necessarily obvious at first: resource optimisation is the key to increasing operational performance, helping to improve the bottom line, and improving the customer experience.

But how can you do this? Which companies in the world are achieving the most efficient sourcing, procurement and purchasing strategies and achieving the ultimate goal of improving the customer experience itself? What are the key factors that determine which solutions work well in practice? What can procurement specialists do to improve their systems and perform at optimum levels?

To gain a better understanding of how to optimise the procurement departments, experts analyzed 11 major companies in four industries and examined the key factors that are central to these organisations sourcing strategies. If there's one thing that technology has made clear over the past decade, it's that every company can do more. Some companies have cracked the code to make the best use of every scrap of procurement spend, while others still are waiting for the real breakthrough to put procurement back at the heart of their business strategies.

Some organisations are now stepping up to that challenge, for instance, by proactively optimising the supplier portfolio, adopting new procurement strategies and putting greater focus on optimisation. According to Gartner's research, which analysed procurement software applications that are being used at 700 purchasing organisations worldwide, most organisations still need to build supply chain resource optimisation and procurement-focused tools to enable a change in the procurement workflow.

Tencent, for instance, aims to be the "best customer-provider" through enhanced procurement service management solutions. Its bid optimisation, for instance, helps boost procurement capacity by extending the market for its goods. China Enterprises Express Group, meanwhile, has leveraged its procurement analytics to drive advanced operations, improve supply chain efficiency and reduce costs. Compared to traditional ERP solutions, it is more challenging to establish business cases for procurement systems as they do not provide insights into critical business outcomes. But these advanced solutions solve that challenge through advanced tools, data and innovative financing models. For example, Tencent uses data to identify how financing is most useful to their customers. Meanwhile, HNA Group was able to collect and analyse hundreds of thousands of online transactions, analyse specific purchase patterns and optimise financing policies. The combination of those strategies led to a 25% reduction in financing costs and 20% improvement in operations for suppliers.

Data is driving today's procurement. It allows organisations to harness a rich database of products and purchase inputs to support their procurement operations, and minimise product wastage. With the increased adoption of the cloud, sourcing and optimisation of information has become easy. Given the breadth of innovations that have evolved in the logistics and supply chain industry, the way in which businesses procure has also transformed. Businesses today are undergoing digital transformation in both how they procure and the information they have access to. Nowadays, the data generated from technology is turning into 'irrelevant' at best or a threat to be mitigated at worst. The changing structure of the market and the changing needs of customers has further changed the industry dynamics in procurement.

Data is driving today's procurement. It allows organisations to harness a rich database of products and purchase inputs to support their procurement operations, and minimise product wastage.

The direct implication of this is the increased need for transparency and managing data in the most agile manner to drive performance. This, in turn, has driven procurement optimisation which is an important process of ensuring procurement has the right data at the right time and in the right format. It allows the procurement teams to determine the most appropriate procurement requirements and the right people to serve them through direct sourcing. Ultimately, this is one way to achieve greater deal management performance and reduce exposure to big contract cancellation.

Supply chain optimisation

Enterprises are moving to procure in multiple currencies, in multiple time zones. Furthermore, for specific products, the supply chain has to deliver to multiple consumers across geographies, with multiple payment methods. Supply chain optimisation is becoming an important part of every procurement process and one in which data must be extracted to help the procurement teams manage a tight supply chain.

Looking at some of our partners' Sourcing, Procurement & purchasing, we understand that the combination with data from the supply chain, does not only improves the same, but it expands and affects the value perceived by the end customer.

Through the procurement optimisation, SAP S/4HANA clients can now leverage their supplier information, gain visibility into their vendors and enter into the best possible contract terms with the highest quality and lowest quantity.

How does this benefit the enterprise?

Shared information with the supplier gives end users the opportunity to view the complete contracts; each contract, from procurement to sales and distribution processes. This is how contracts get optimised and optimised further by sharing those contracts with other aspects within the enterprise. This optimisation not only involves your supply chain, but the value added further is identified by integrating the contract management and the procurement process into the SAP Business Warehouse.

A partner's network and sourcing in the right ecosystem can enhance the organisation purchasing decisions; making it faster and accurate. This is a must-have for businesses to be successful, with a robust supply chain comes great buying power. By utilising a multi-vendor sourcing centre, the organisations supply chain will be able to use a wider range of suppliers, increase their capacity, utilise your preferred supplier for more sensitive needs and increase your potential for optimisation, increasing the value of your supply chain.

Using a procurement optimisation, you can also optimise the buying power of your organisation by sourcing the right products, rather than spending money on the cheaper one.